Welcome to our capabilities page

Here we will give you an overview of all the inhouse processes we can do here at BNOS Meditech Limted.

Here we will give you an overview of all the inhouse processes we can do here at BNOS Meditech Limted.

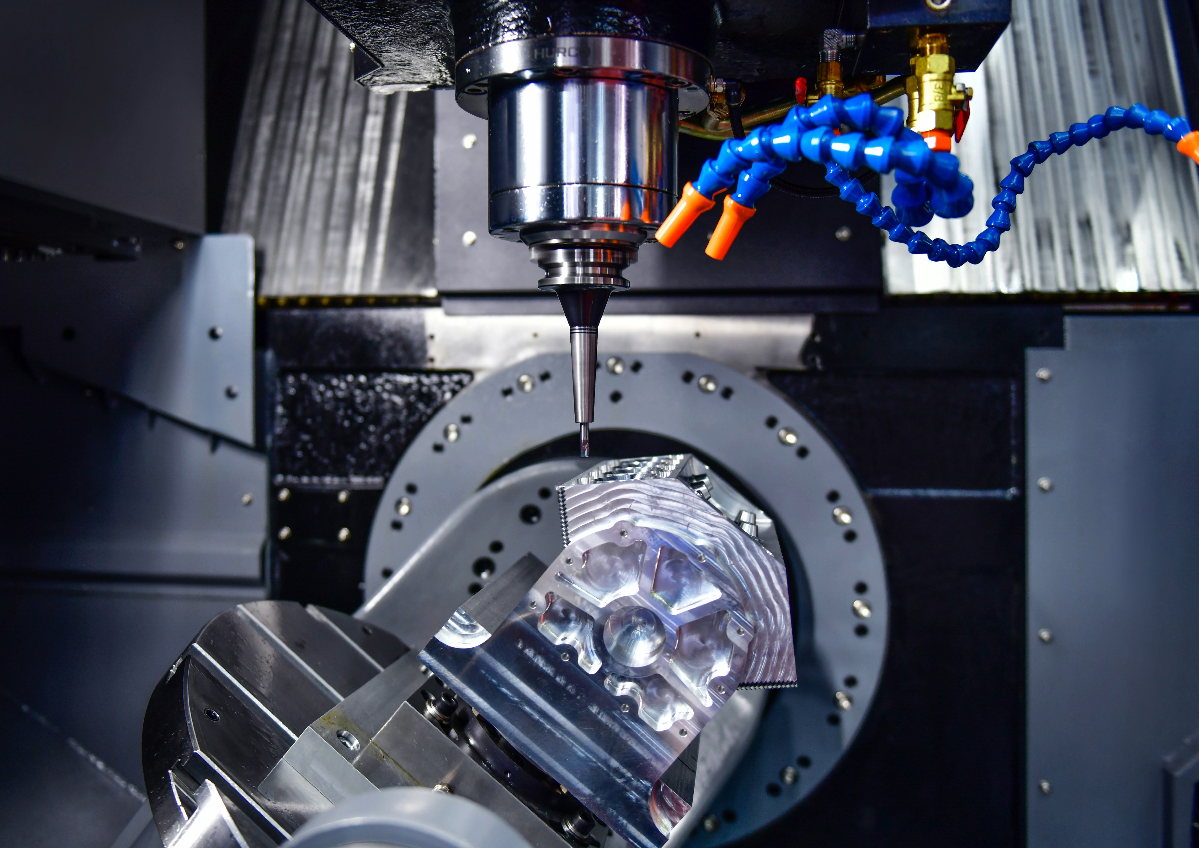

We have a full CNC machining centre with numerous sized CNC Machines which allows us to machine all of our components inhouse, which reduces our supply chain, enabling us to deliver high quality products, quickly. We machine our products from a number of materials such as brass, aluminum, stainless steel & plastic.

Benefits of CNC machining inhouse:

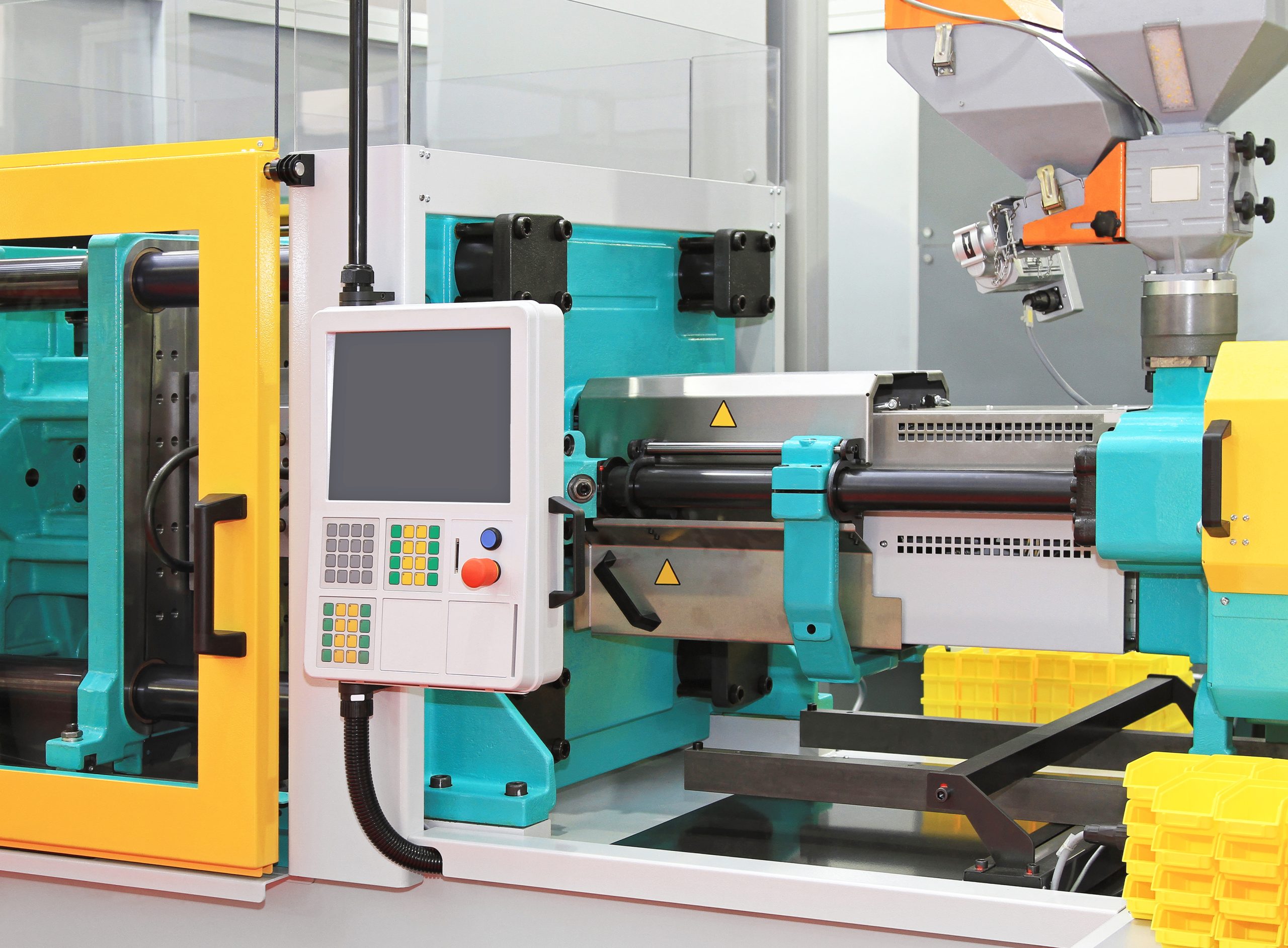

We have recently invested in a plastic moulding centre allowing us to produce high quality plastic moulded products / components for a wide range of industries such as:

Services we offer:

We have a full plating plant onsite which allows us to plate our components quickly and ensure we get the same high quality finish, every time!

Advantages of Electroless Nickel Plating:

We have a design & development team working on our new products whilst also improving exsisting products with CAD (Computer-Aided-Design).

This system allows our team to create 3D computer models so the designs can be viewed from all angles and with a range of materials. This ultimately allows us to create more accurate designs inhouse ensuring less disruption to our production and avoiding costly errors.

Having a dedicated inhouse design team also gives us the opportunity to work closely with our customers and ensure they are getting exactly what they need. We will try our upmost to provide the desired version of a product to suit the customers needs & their national requirements.

All of our products are assembled, tested and packed onsite to ensure the highest quality products leave our factory. By assembling & testing our products in-house rather than outsourcing, we can reduce lead times, improve production flow and minimise setbacks. This helps to improve overall productivity resulting in a more efficient manufacturing process.

We also have a dedicated product servicing team to ensure full support is available for our customers and their products in the field. By customer request, regular servicing of all products is available to be returned to us for an initial examination or we do offer training courses so that a customer’s engineer may learn to carry out various levels of service on their Meditech products.

Get in touch with our experienced team today!